S

ometimes the best things really

do

come to those who wait.

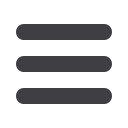

Golf Club de Genève was

established in 1921, and in 1972

commissioned Robert Trent Jones, Sr.,

one of ASGCA’s founding members, to

design its existing course on 100 acres

of the Bessinge estate. Overlooking

the city of Geneva and its famous lake,

golfers on this impressive parkland

course also enjoy Mont Blanc and the

Alps as a backdrop.

In 1982 the club hosted the

Women’s World Amateur Team

Championship and since 1991 it has

been the venue of The Rolex Trophy

on the European Challenge Tour.

Wanting to provide firm,

dry playing conditions for its

membership, while protecting the

integrity of the original design, in

2015 the club commenced a full

18-hole renovation. The design effort

was led by architects Bruce Charlton,

ASGCA, and Mike Gorman from the

firm of Robert Trent Jones II, ASGCA.

In addition to a major investment in

irrigation and drainage throughout the

course, a key aspect of the renovation

was to enhance the rootzone mix

to improve the performance and

playability of green surfaces.

The first phase of the renovation,

which was completed in 2015,

included the harvesting of sod from

existing greens. This process began

last September, and was followed by

the installation of a new rootzone

blend of sand and Profile Porous

Ceramics. The harvested sod was

retained and re-laid over the new

surface to begin the growing process.

The mix was specifically chosen

after sand samples were sent from

two different quarries and tested

at a USGA lab. Recommendations

were made to include Profile

Porous Ceramics – Greens Grade,

manufactured by Profile Products, in

both the greens and tee mix.

This design would provide an

optimum long-term balance of

air- and water-holding pore space,

improved nutrient retention, and

better stability.

Profile Products assisted with

rootzone testing to ensure the correct

sand was chosen. Although the

project was located in Switzerland,

the rootzone mix came from just

across the border in France.

Gavin Kelly, the European Sales

Manager for Profile Products, visited

the quarry to assist with the blending

and mixing of sand and the Profile

Porous Ceramics.

“It was important that the right

sand was selected for the project,

and that we tested the physical

characteristics of the mix,” noted

Kelly. “We first tested the sand on

its own, and then tested the sand

blended with the Profile Ceramics to

ensure that we had favorable levels

of infiltration, water-holding, and air

in the mix.”

In total, 550 tons of Profile Porous

Ceramics will have been blended

Golf Club De Genève

|

Jeff Langner

Getting the

right mix

CASE STUDY

20

|

By Design

Jeff Langner of Profile Products

explains more about the selection of a

new rootzone mix for the renovation of

Golf Club de Genève in Switzerland