[

] 314

I

nternational

C

ooperation

on

W

ater

S

ciences

and

R

esearch

such as turbidity, dissolved organic carbon, residual

chlorine, NH

4

-N, NO

3

-N, NO

2

-N, oxidation reduc-

tion potential and so on are automatically monitored

by sensors installed at intake, water treatment plant,

distribution reservoirs, distribution pipelines and

taps. The expert decision system consists of automatic

control dosing systems for coagulant and chlorine, and

a water supply pump schedule system. The system

assists the operator to make fast and accurate deci-

sions for optimum operation.

The H-Eco system is expected to reduce operation

costs (chemicals, electricity and so on) through a

remote control system. It is also expected to provide

stable operation of the water treatment plant through

a real-time monitoring and remote expert decision-

making system.

Packaged water treatment system in

Ulaanbaatar, Mongolia

KICT has developed multi-purpose small-scale water

treatment package systems: a regionally customized

water treatment system, a mobile emergency water

treatment package system, and an integrated manage-

ment system for distributed water treatment plants.

This project has set targets such as selecting a

suitable water quality guideline and drawing up key

technology applicable to local areas. The system is

named the ‘E

3

system’ because it achieves the three

targets of high efficiency, cost-effectiveness and low

energy consumption.

Mongolia was chosen as a target country in which

to test the operational safety of the system under

various weather conditions, due to its intense cold

in winter. An active on-site investigation was carried

out at Ulaanbaatar by building cooperation with the

Mongolian Government. As a result of the water

quality analysis, a skid-type pilot system was targeted

to control manganese and bacteria. The system

was installed in a 20-foot container compliant with

International Organization for Standardization stand-

ards. A manganese-coated sand filter was chosen to

control manganese and particle contaminants in the

water. The ultraviolet disinfection system followed

to remove pathogens. The water treatment package

system was designed with a capacity of 24 m

3

per day,

supplying safe drinking water to between 3,000 and

6,000 people in a day, assuming that one person typi-

cally consume 4-8 litres of water daily.

KICT has a plan to improve system performance

through the long-term operation. This operational

know-how is expected to provide Mongolia with safe

and reliable water distribution by providing locally-

available resources and an operating manual for

sustainable operation and maintenance. In addition,

technological support and business interchange with

the Mongolian Government will be carried forward

in a scheme established by mutual agreement. This

corporation is expected to be helpful to water industry

development between Korea and Mongolia.

integrity, was reinforced. An economical maintenance process was

achieved by optimization and modification in part of the pump

operation, membrane cleaning procedures and membrane operation

modes. The total waterworks system including distribution lines

was also improved.

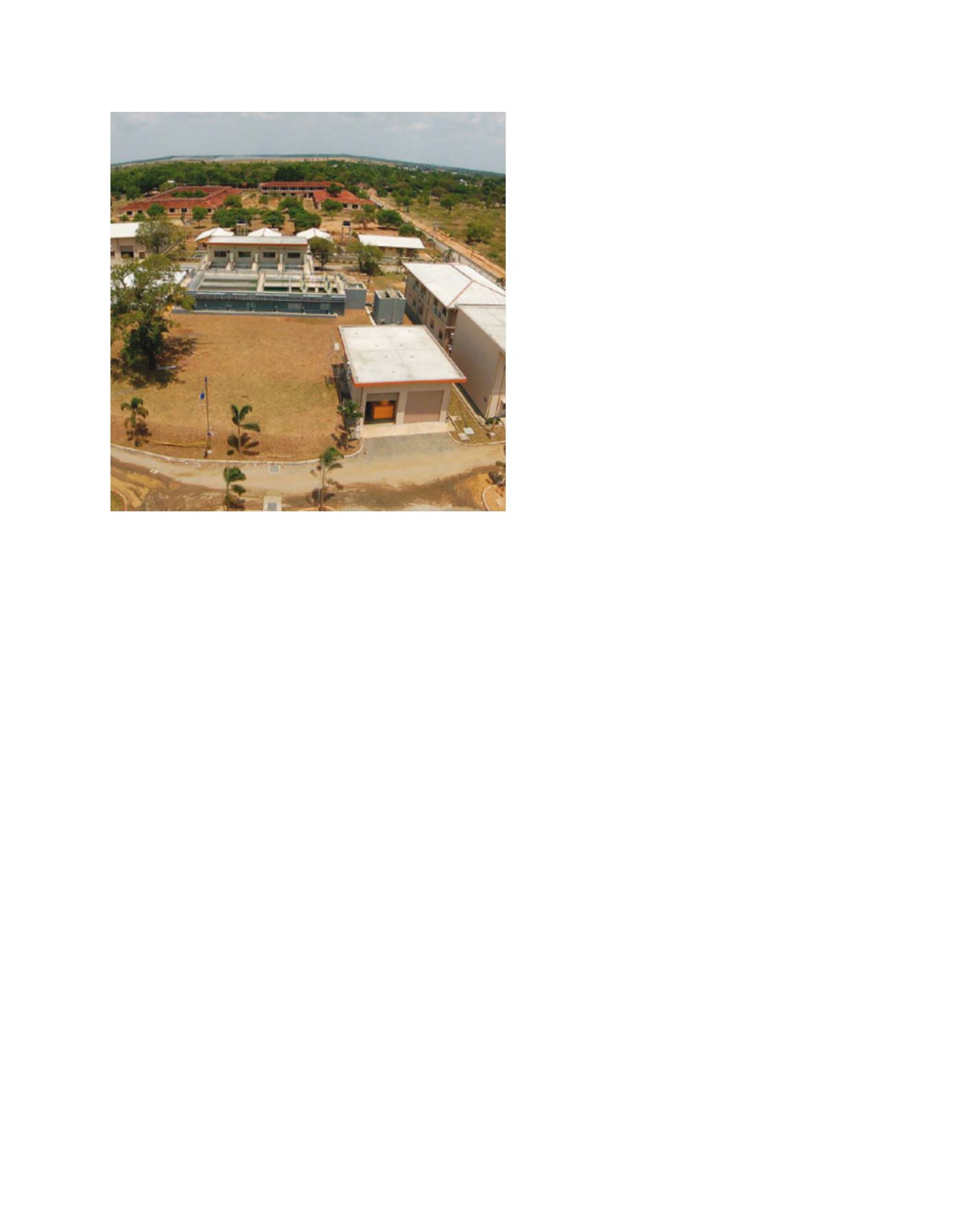

The H-Eco water supply control system in

Polonnaruwa, Sri Lanka

The Polonnaruwa drinking water treatment plant was designed

and constructed at Polonnaruwa, Sri Lanka in 2012 by Hyundai

Engineering with support from the Asian Development Bank and

the Government of Sri Lanka. The plant purifies river water by a

conventional process of intake, coagulation, sedimentation, sand

filtration and disinfection. Its capacity is 13,500 m

3

per day and

it supplies safe drinking water to the people of Polonnaruwa city.

In many cases, water treatment plants in developing countries are

not operated properly due to problems such as a lack of skilled oper-

ators and maintenance experience. In order to solve this problem,

Hyundai Engineering has developed the H-Eco water supply control

system, which is a remote monitoring and operator support system.

The system collects the water quality and flow rate data from sensors

installed in intake, water treatment plant, distribution pipelines

and taps. The collected data are analysed and assist the operator to

manage the water treatment system efficiently by providing online

information about optimal operating conditions in the water treat-

ment plant. The H-Eco system networks several water treatment

plants scattered around the world with the main office of Hyundai

Engineering in Seoul. It also provides solutions for operation and

maintenance to the operators in the plants.

The H-Eco system consists of a water quality and water flow rate

monitoring system, a remote expert decision system and remote

monitoring and operator support system. In the water quality and

flow rate monitoring system, water flow rate and water quality

Polonnaruwa drinking water treatment plant in Sri Lanka

Image: Hyundai Engineering